NEWS

- ISO 9001 for I-CDBKZInstitute – Center of Excellence in Gear Wheel Research of the Kalisz Academy President Stanisław Wojciechowski received a quality management system certificate compliant with the requirements of ISO 9001: 2015 in the field of laboratory… Read more: ISO 9001 for I-CDBKZ

OUR OFFER

Measurements of shape deviations, true position and run-out

Measurements of contour and surface roughness

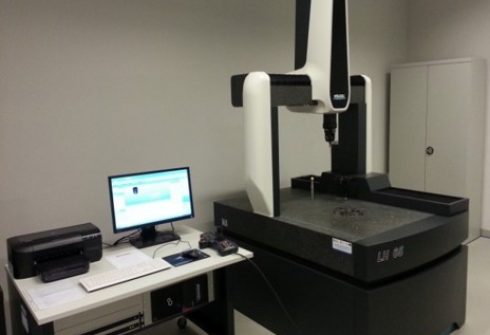

3D coordinate measuring, full-field scanning & inspection, quality control, reverse engineering, GD&T analysis

Static, compression and bending examination of materials

Preparation of metallographic specimens to determine microstructure

Hardness and microhardness measurements

Determination of chemical composition of alloys using optical emission spectrometry method